A resource estimate consists of a statement of the tonnage of the resource and its grade:

$Gross revenue = Grade X Tonnage

In bauxites, reliable tonnage calculations depend on reliable volume calculations. When thickness is more variable than grade, reliability of resource estimates may depend primarily on thickness estimates. Traditional thickness estimation is derived from regularly spaced drilling that is seldom able to accurately model the ore surfaces. UltraGPR is capable of accurately identifying the bottom of ore with more detail than drilling and at a fraction of the cost. The result is a more accurate volume calculation.

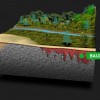

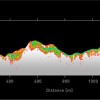

In most lateritic and karstic bauxites, drilling is often inadequate to determine actual deposit shape. Three-dimensional radar models are constructed by scanning the region along tightly-spaced profiles. The depth to bauxite and the thickness of bauxite is shown in real-time during surveying, allowing the survey to be adapted to ensure an accurate volume determination.

The resultant profiles are processed and positioned using DGPS data. The output of this process is a string of X, Y, Z positions for the pit floor, which are then shifted vertically to reflect the ground topography, based on a digital terrain model.

The final 3D model of the deposit is produced by gridding these points to create a terrain model of the top and bottom of the bauxite horizon in the case of lateritic bauxites, or the pit floor in the case of karstic deposits. All data are provided in local mine co-ordinates. These pit models may be produced in any suitable format for AutoCAD, Datamine, Vulcan, Gemcom, Surpac, etc. Volumes are also provided for each pit at various overburden stripping depths, as well as the surface area of the mineable pit.